Description

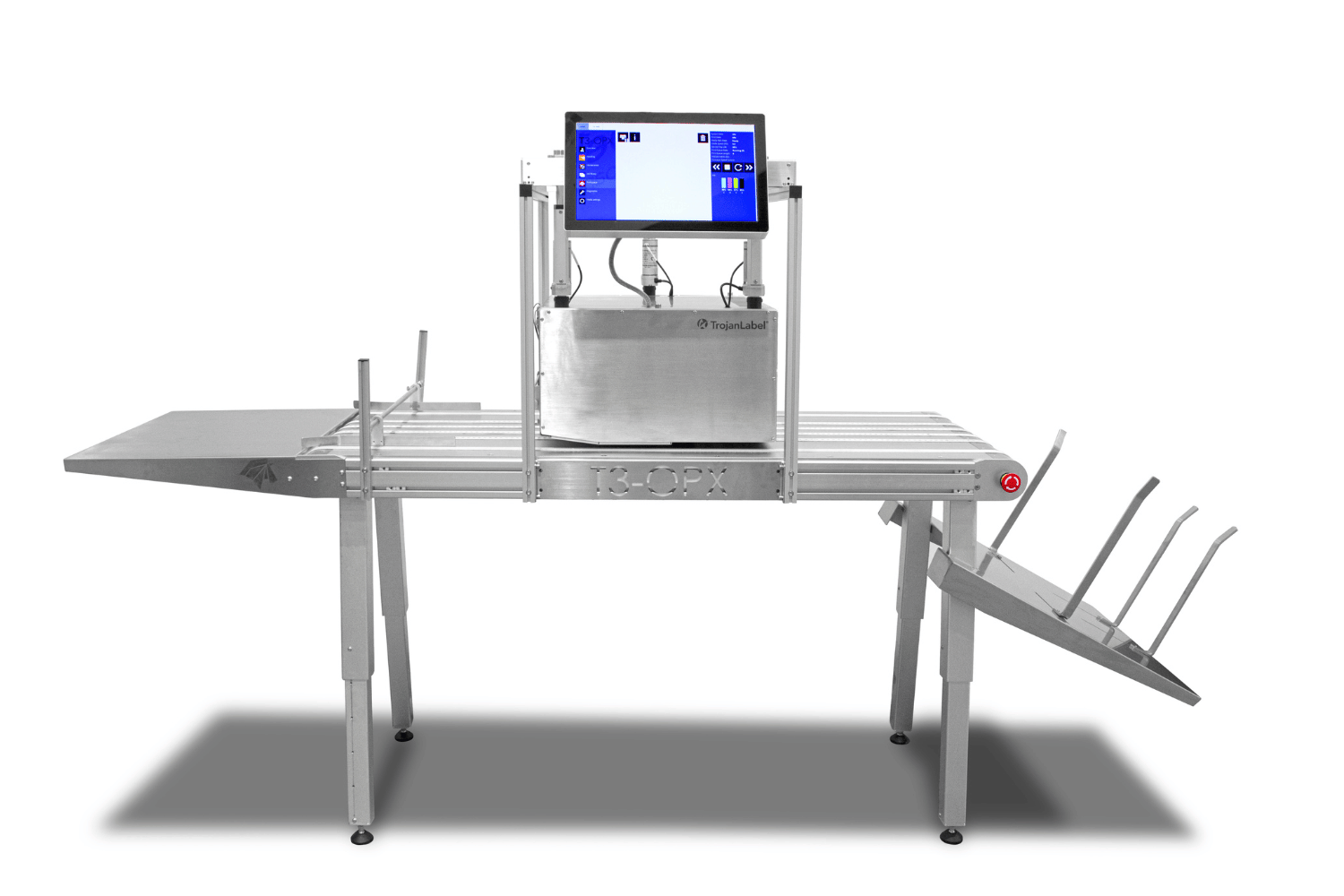

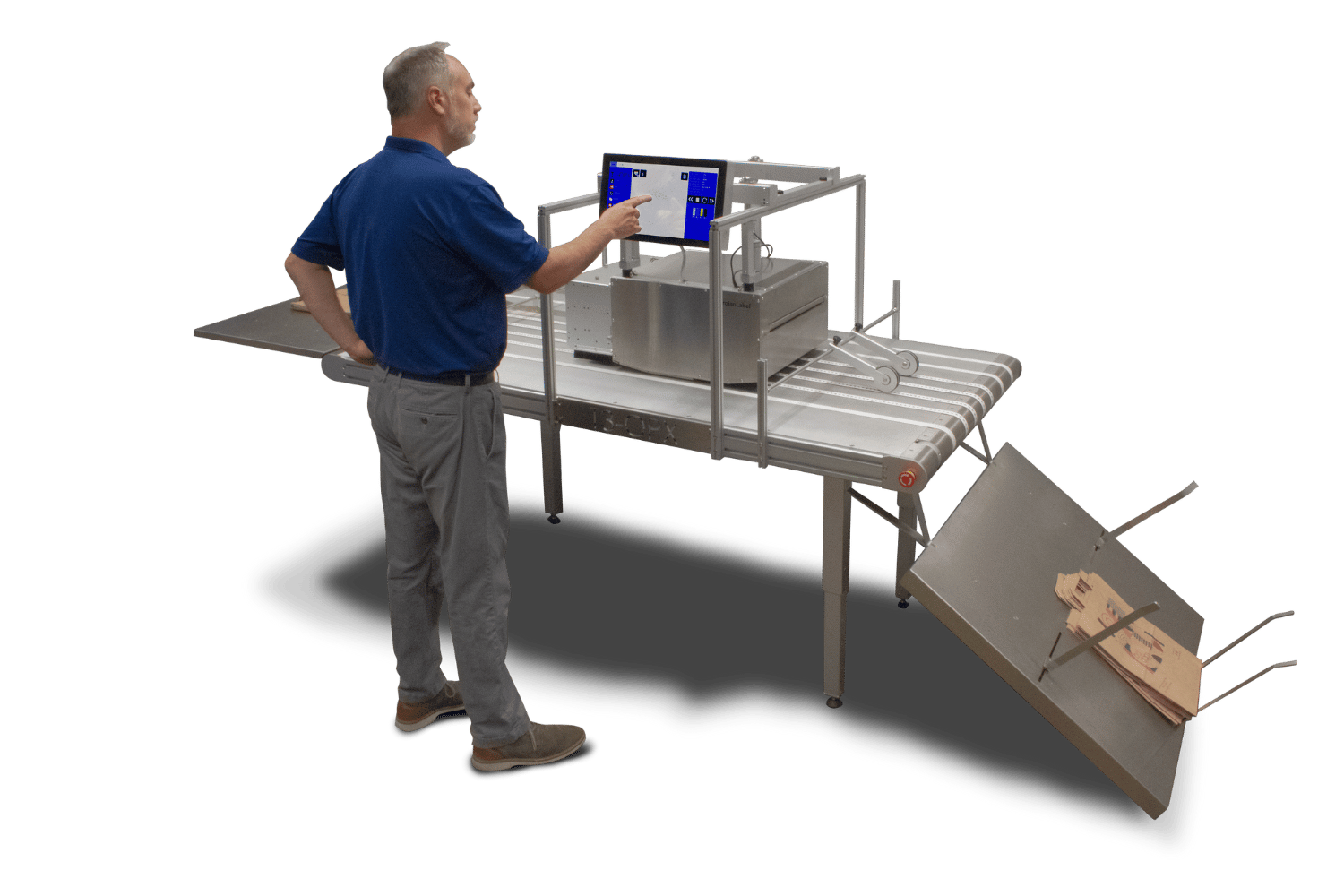

The T3-OPX represents a next-generation, direct-to-package solution. Offering superior, wide-format print

capabilities at fast speeds, and the ability to print on a variety of materials like postcards, boxes, paper bags,

wooden planks, or thicker objects like blister envelopes or folded boxes ready for shipment, and more, the

T3-OPX allows for late-stage customization and packaging and design versatility.

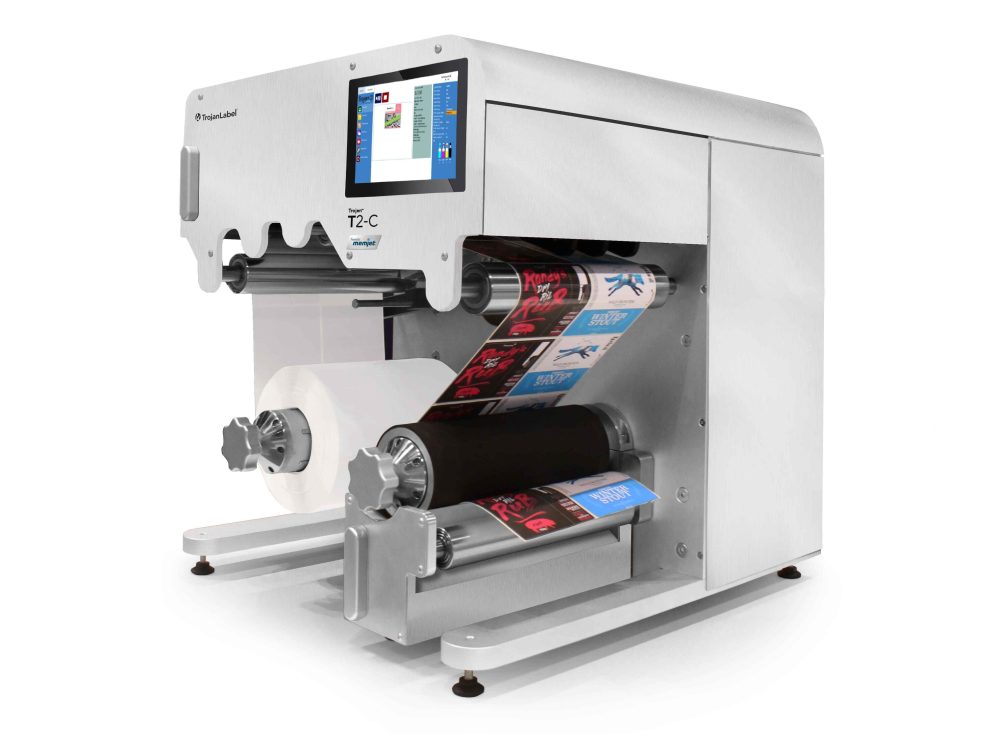

Conveyor Table or Printing Equipment Manufacturers

The print module lends itself to easy integrations with 3rd party equipment. Our technical team can assist

you with drawings, I/O controls, software APIs, and all necessary documentation to make the integration

process effortless. You can tailor a solution to meet your customer’s unique needs faster than ever before.

The T3-OPX offers extended print area, extended resistance to the elements, and extended print head life.

Enabling high-quality, full-colour printing directly onto materials with ink-receptive surfaces such as

cardboard, postcards, boxes, paper bags, wooden planks or thicker objects like blister envelopes and folded

boxes ready for shipment, the T3-OPX uses pigmented inks that provide superior durability and have been

tested for optimized lightfastness, water durability, and scratch resistance. Designed for 24/7 production, the

T3-OPX mounts on host systems with runs up to 18 ips; automatically adjusting for variances in speed,

timing, and spacing. With brilliant atomized height calibration and stable, high-quality production, the T3-

OPX delivers ROI to businesses by easily expanding products and services to attract new and current

customers with private labelling for seasonal or promotional events. Versatile and easy-to-use, it provides a

perfect solution for label converters, print shops, manufacturers, contract packaging solutions, and

secondary label logistic partners.

– Pigmented inks provide superior durability, optimized water resistance, lightfastness, and scratch

resistance

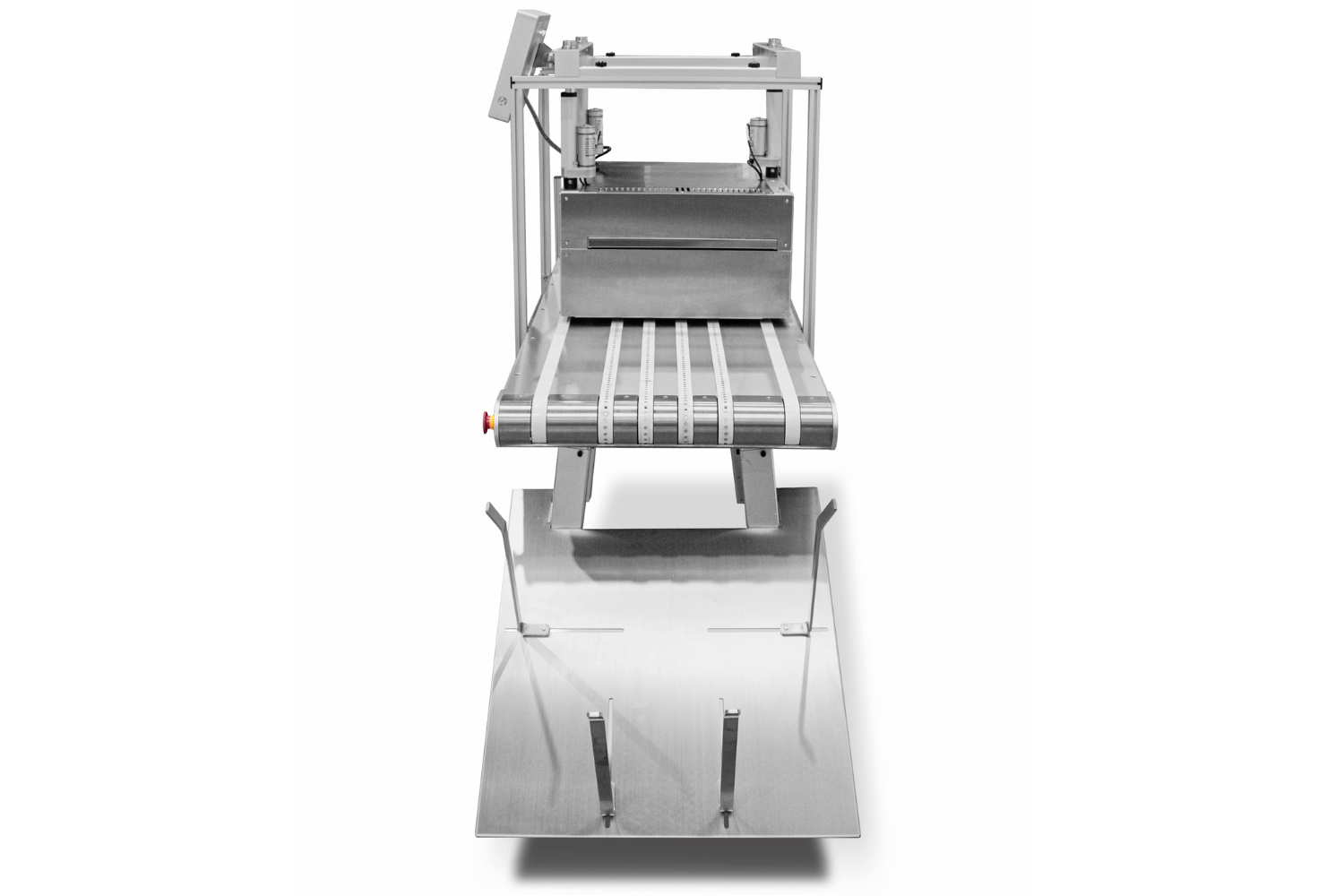

– Unique, self-calibrating, adjustable product height ensures optimal print quality while providing fast

product changeovers, helping you to meet rigorous production demands

– Automatic height calibration for rapid changeovers and accurate print height for substrate

thicknesses ranging from 0 – 4” (0-100mm).

– High-speed printing and product transport – variable up to 18 ips, delivers the optimal balance of

print quality and productivity.

– Feeder table and adjustable media guides enable easy integration with a variety of automatic feeder

options with conveyor table.

– User-friendly intuitive interface and built-in job library allow for easy operation and recall of product

configuration parameters.

Reviews

There are no reviews yet.